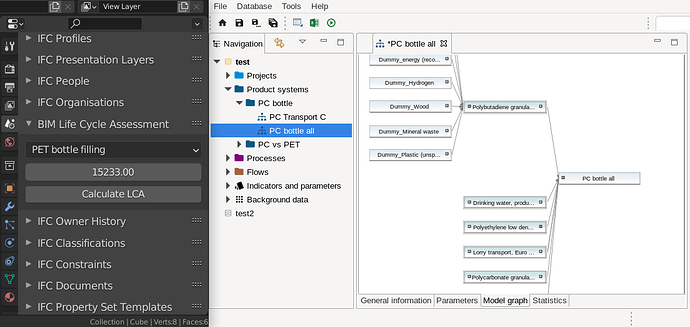

The carbon results of the Eyefficiency tool are compared to previous studies at two of Eyefficiency's pilot test sites. Given those goals, the development team chose to use a hybrid LCA approach with UK-based process and environmental extended input–output inventories. Here, we describe the LCA approaches tested for use in Eyefficiency, with the goals of creating an easy-to-use, open source tool that is also easy to maintain and update. The Eyefficiency tool, discussed here, develops a universal Life Cycle Assessment (LCA) methodology for cataract surgery to identify opportunities for sites to minimize the footprint of cataract surgical services and increase access to cataract surgery for patients worldwide.

However, there is currently no audit tool which facilitates capture of routine cataract surgical productivity, solid waste, carbon, and cost-related data which could be used for global benchmarking, learning, and improvement.

A great deal of progress has been made in increasing cataract surgical rates or productivity, and associated cost containment. If the results are to be used as a basis for marketing or certification, however, the product should undergo a thorough analysis (SimaPro ®), which is a bit more complicated and requires some prior software knowledge.Cataract surgery is the most commonly performed medical procedure in the world but there continues to be a large, unmet requirement for more surgery, with cataract still accounting for one third of all global blindness. If the analysis is only to be used to give an indication of where and what the greatest environmental impact is, use a simpler method such as Eco Indicator 99, Eco Scan 3.0 or Eco-IT. Which one to use depends on how complicated the product is and how the results will be used. There are several more or less advanced versions of LCA tools. involved in all life cycle stages of a product (from the extraction of raw materials needed to produced it until it is no longer used and thrown away or recycled). The LCA tool analyses the impact of the energy used, release of toxic substances, natural resource use, etc.

A life cycle assessment (LCA) is used to identify the environmental risks of existing and planned products, services and manufacturing processes as well as identify strategic improvement opportunities.

0 kommentar(er)

0 kommentar(er)